A robot with laser eyesight

Precise positioning with the sensor and software system from norisTEC

Source: norisTEC F&E

Precise positioning of tools and workpieces is among the most demanding tasks in automation. Especially with flexible robot systems, accuracy determines whether machining remains reproducible, efficient, and economical.

norisTEC GmbH has developed an innovative system of hardware components and a modular software toolbox for this purpose — a real laser eye for the robot.

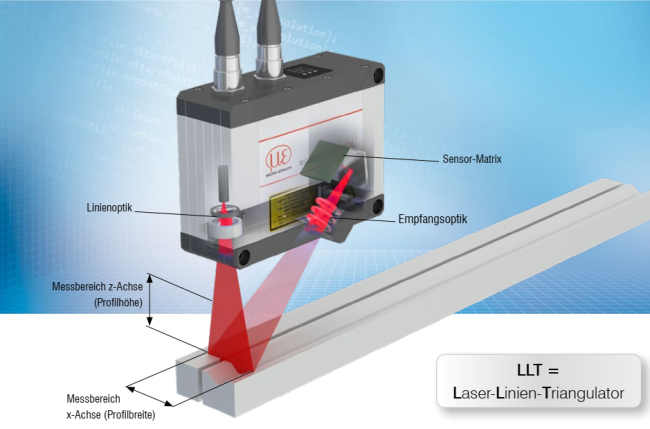

The system makes it possible to align the tool of a 6‑axis articulated robot with the workpiece with high precision, without contact, quickly and without complex calibration. The core component is a laser line triangulator (LLT) that captures height profiles and edge structures of the workpiece with impressive resolution and accuracy. In combination with the noris

TEC

software, a digital image of the environment is created, giving the robot millimeter-accurate orientation.

Why a laser triangulator instead of a camera?

While camera-based systems are often sensitive to ambient light and require shielded measuring chambers, the laser triangulator works almost independently of ambient light.

Its concentrated light line delivers razor-sharp height profiles even with short exposure times, entirely without a light chamber or special lighting.

“The camera is essentially wearing sunglasses and only sees the very bright laser,” one developer aptly put it.

Another advantage: The integrated evaluation system in the sensor directly converts the recorded height profile into real position values in millimeters – distortions such as those found in conventional camera optics are eliminated or compensated for by the specialized sensor software. This means that a kind of online preprocessing and scaling takes place directly within the sensor itself.

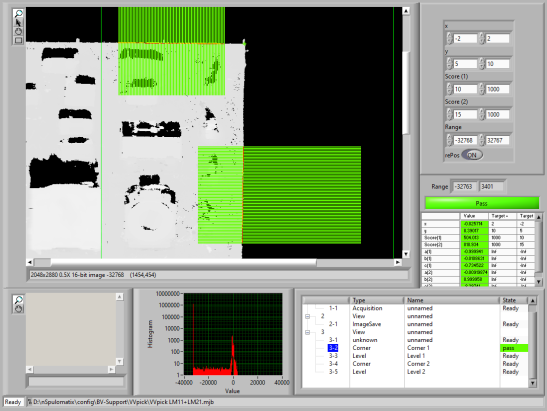

Able to learn – thanks to its own specialized norisTEC image processing toolkit (NI Vision)

After the components are scanned with the laser line, a 3D profile image is generated and loaded into the image processing system. This involves reducing the image to a pseudo 2D height image, which can be further processed using various selectable modules from the norisTEC-MV-Toolkit, based on NI Vision.

Source: norisTEC F&E

By cleverly combining these modules (edge detection, line interpolation, intersection edge calculation, area determination and much more), marker points can be determined from the image, which are reflected back and serve as position correction for the robot. These modules can be learned by the user in your application on components, and can also be relearned, expanded, and modified at any time. It features an intuitive user interface. This allows the robot to see exactly where it needs to grip, almost down to the submillimeter. He has laser vision as a result.

Precision from a single source – hardware and software perfectly integrated

The solution is designed for the entire Mitsubishi MELFA robot family, but can also be adapted to systems from other manufacturers.

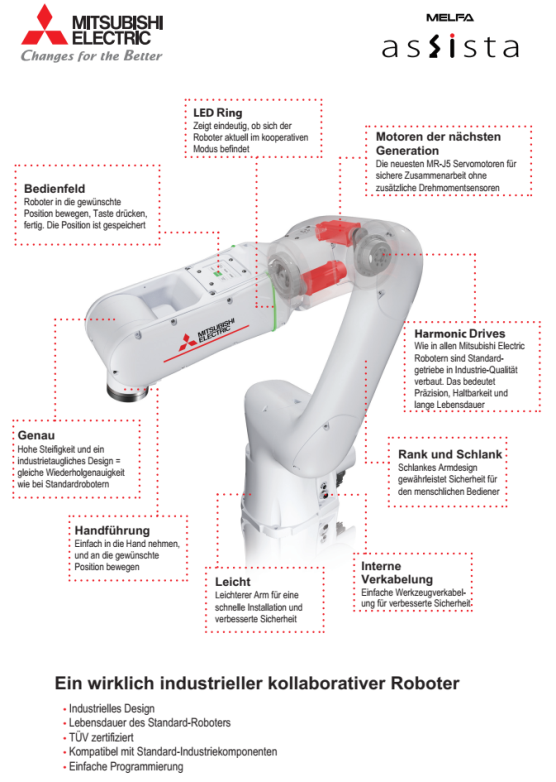

The current application uses a MITSUBISHI ELECTRIC MELFA ASSISTA RV-5AS‑D – a collaborative robot that combines the precision of classic industrial robots with the safety and flexibility of a cobot.

The system can be configured in two hardware variants:

- Variant 1: The laser triangulator is permanently installed on the robot arm; tools such as screwdrivers, milling cutters, or test probes are mounted with a fixed reference. The exact positional relationship between the laser and the tool is calibrated once.

- Variant 2: Lasers and tools can be flexibly docked during the process using an automatic tool change system.

Flexibility meets safety – automatic tool change system

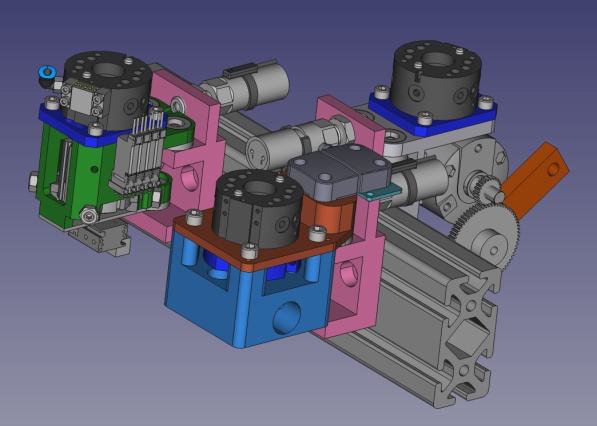

In parallel with the sensor solution, norisTEC has developed a complete concept for safe automatic tool changing.

The different robot hands – including the “scanner hand” – are docked via a pneumatically controlled standard system from Schunk. In addition, a specially developed tool parking system was created with locked, spring-supported and safety-monitored parking stations.

Source: norisTEC F&E + Konrad Lechner GmbH & Co. KG

This allows the collaborative robot to pick up “dangerous” tools without endangering the operator’s safety: The system automatically switches between collaborative and high-speed modes, depending on the tool and operating condition (safety door condition).

A color-coded signal from the robot always informs the operator about the current operating mode. If the user opens a safety door during a high-speed operation, the robot stops safely – if they enter the safety zone during collaborative operation, the robot automatically reduces its speed.

Well-thought-out integration – right down to cable management

Source: norisTEC F&E

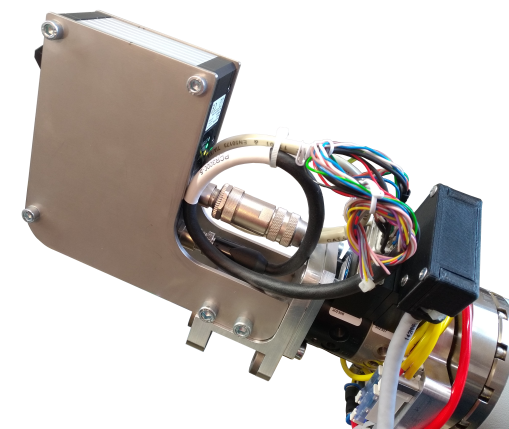

To make the system as compact and robust as possible, norisTEC also developed an internal multiplex system for the signal routing of the MELFA ASSISTA.

Depending on the mounted robot hand, the same internal cable package can be used as a Gigabit Ethernet line, as a digital I/O connection, or for controlling pneumatic valves – automatically switched via the robot controller.

This eliminates the need for disruptive external cables, and the hand change is tension-free and reliable.

Even the ASSISTA itself has been optimized: One of the factory-installed electrical lines was replaced by a pneumatic line, so that all supplies are now routed internally to the tool holder and via the automatic interchangeable flange. The result is a clean, space-saving and industrial-grade solution.

Conclusion

With the combination of laser triangulator, intelligent software and sophisticated system integration, norisTEC has created a tool that teaches robots to see – precisely, robustly and flexibly.

Whether for precise positioning, testing or assembly – the system offers a solution that seamlessly masters the transition between classic industrial automation and modern collaborative robotics.