for Control Units, HMIs, MMIs and general LED systems in the industrial, aerospace and automotive sector

norisTEC will supply you with fully or semiautomated end of line test systems for a wide range of control units, HMIs and MMIs.

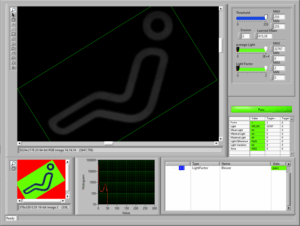

Industrial image processing is an integral part of typical end of line tests.

We are relying on our own native LabVIEW IMAQ Vision Toolkit, the nVisionService. This enables us to meet customer requirements quickly, reproducibly and cost-effectively.

Using high quality GigE Vision cameras provides the perfect match of accuracy, speed and price.

Product Testing

In general, product testing requires certain test steps:

- Verification of symbols and symbol positions using pattern matching (controls and display)

- Functional testing of symbol groups including short-circuit detection

- True-colour LED assembly verification

- Light density measurement of all elements (backlight, function)

- Evaluation of average light density

- Evaluation of homogeneity within the symbols and in between symbols Determination of compensation values used in the UUT’s led-controller

- Retesting of the corrected lighting

nVisionService

The norisTEC nVisionService is developed natively in NI LabVIEW and uses the NI IMAQ Vision function-alities running on a Standard Windows PC (embedded or industrial).

It already includes common measurement and test functions required for product testing. It can easily be integrate it into a customer application and environment using a TCP transport protocol.

The user-friendly UI enables you to adapt your system by yourself.

Why nVisionService?

Requirements

Industrial image processing is an essential part in modern EOL systems with the need to cover various requirements:

- Symbol verification

- Position verification

- Colour verification

- Functional testing

- Light density measurement

- Calculation of compensation values

Solutions

We are offering custom-build and cost-effective vision solutions based on a flexible and potent platform.

- nVisionService: an NI IMAQ Vision based vision toolkit

- Measurement-job administration

- Teach and parameter software

- Any common GigE machine vision cameras

Features

- Light density measurement in cd/m2

- Camera mounting at defined distance and field of view

- Shading correction against integrating sphere

- Compensation values for each LED colour

Newly designed nT LightDensity Measurement

In order to obtain comparable, absolute brightness information, the light density needs to be specified in cd/m². Therefore, we are always integrating the cameras into our systems in the same way:

- Fixed camera mounting on stable mounting brackets

- Camera adjustment at a defined distance and field of view

- Shading correction against integrating sphere

- Compensation values for each led colour using a custom made testing dummy

Colour Correction

Our Vision Toolkit acquires 12-bit greyscale images while applying a shading compensation.

The light density value then is determined for individual elements using the LED color correction and taking into account the image recording parameter, exposure time and gain.